Model 5215 Standard Cold Gun System (One Cold Outlet)

Applications

- Tool sharpening

- Drill and cutter grinding

- Routing

- Plunge and form grinding

- Milling

- Surface grinding

- Drilling

- Tire grinding

- Band sawing

- Plastic machining

- Laser cutting

- Chill rolls

- Setting hot melt adhesives

Advantages

- Improves production rates

- Prevents burning

- Extends tool life - reduces breakage

- Improves tolerance control

- Prevents smearing of metal or plastics

- Finished part is dry

- Eliminates wheel loading

- Low cost

- Compact, lightweight, portable

- No moving parts - maintenance free

- Quiet

- No coolant cost

- No electricity

Accessories

Single Point Hose Kit - (included with the Model 5215 Cold Gun and Model 5230 High Power Cold Gun) is recommended for applications where a concentrated airflow is needed such as drilling and grinding operations.

Dual Point Hose Kit - (included with the Model 5315 Cold Gun and Model 5330 High Power Cold Gun) is recommended for applications where the heat is generated over a larger surface area such as band sawing, milling, chill rolls and hot melt adhesives.

Cold Gun Systems

Four systems are available:

Model 5215 Cold Gun System (one cold outlet) includes Cold Gun, Single Point Hose Kit, 3/8" (10mm) Cone Nozzle, 1-1/4" (32mm) Fan Nozzle, Manual Drain Filter Separator.

Model 5315 Cold Gun System (two cold outlets) includes Cold Gun, Dual Point Hose Kit, (2) 1/4" (6mm) Cone Nozzles, (2) 1" (25mm) Fan Nozzles, Manual Drain Filter Separator.

Model 5230 High Power Cold Gun System (one cold outlet) includes High Power Cold Gun, Single Point Hose Kit, 3/8" (10mm) Cone Nozzle, 1-1/4" (32mm) Fan Nozzle, Automatic Drain Filter Separator.

Model 5330 High Power Cold Gun System (two cold outlets) includes High Power Cold Gun, Dual Point Hose Kit, (2) 1/4" (6mm) Cone Nozzles, (2) 1" (25mm) Fan Nozzles, Automatic Drain Filter Separator.

Cold Gun Performance |

|||||

| Pressure Supply | Air Consumption | Sound Level | |||

| Model # | PSIG | BAR | SCFM | SLPM | dBA |

| 5215 Cold Gun | 100 | 6.9 | 15 | 425 | 70 |

| 5315 Cold Gun | 100 | 6.9 | 15 | 425 | 70 |

| 5230 High Power Cold Gun | 100 | 6.9 | 30 | 850 | 82 |

| 5330 High Power Cold Gun | 100 | 6.9 | 30 | 850 | 82 |

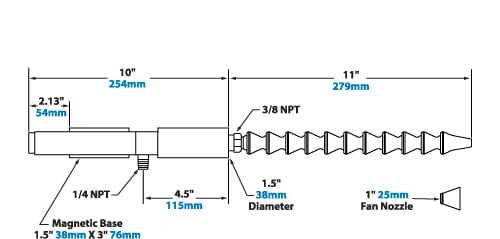

Cold Gun Dimensions |

|

How the Cold Gun Works |

|

The standard Cold Gun and High Power Cold Gun incorporate a vortex tube to convert an ordinary supply of compressed air (1) into two low pressure streams, one hot and one cold. Secondary air is drawn in (2). The Cold Gun's hot airstream is muffled and discharged through the hot air exhaust (3). The cold air (4) is muffled and discharged through the flexible hose (5), which directs it to the point of use. Easy mounting and portability are provided through the use of an attached magnetic base (6). |

Other Considerations

Controlling the Cold Air

The EXAIR Cold Gun gives instant cold air when filtered compressed air is supplied to it. Cycling on and off is a good way to save air. For on and off control, use a Model 9012 Manual Shutoff Valve. To turn the Cold Gun on with the machine, a solenoid valve may be used and wired through the machine control switch. This method is ideal for hand grinders and drill sharpeners.

The Compressed Air Supply

The Cold Gun is designed to use full line pressure of 80-100 PSIG (5.5-6.9 BAR). Temperature drop and flow are reduced when lower input pressures are applied. The use of clean, filtered air is essential to the operation of the Cold Gun. A filter separator that removes moisture, dirt and other particulates from the compressed air is included with each Cold Gun System. An optional Oil Removal Filter is also available.

Selecting The Right Model

Cold Gun Aircoolant Systems are available with either a Single Point or Dual Point Hose Kit.

The Single Point Hose Kit (included with the Model 5215 Cold Gun and Model 5230 High Power Cold Gun) is recommended for applications where a concentrated airflow is needed such as drilling and grinding operations.

The Dual Point Hose Kit (included with the Model 5315 Cold Gun and Model 5330 High Power Cold Gun) is recommended for applications where the heat is generated over a larger surface area such as band sawing, milling, chill rolls and hot melt adhesives.

A Cold Gun System with the Model 5901 Single Point Hose Kit can be easily converted to a “dual point” system with the purchase of the Model 5902 Dual Point Hose Kit.

Need More Cooling?

EXAIR’s High Power Cold Gun Aircoolant System produces twice the airflow of the standard Cold Gun, doubling the cooling capability. It produces cold air at 54ºF (30ºC) below the supply air temperature so the air is as cold as possible without freezing up. Two systems are available: the Model 5230 High Power Cold Gun with Single Point Hose Kit and Model 5330 High Power Cold Gun with Dual Point Hose Kit.

-

Model 5215 Standard Cold Gun System (One Cold Outlet)

Model 5215 Standard Cold Gun System (One Cold Outlet)