Your Cart

You have no items in your shopping cart.

Close

Close Creating an account has many benefits:

Type 303 Stainless Steel - All of EXAIR's Liquid Atomizing Nozzles are constructed with Type 303 stainless steel, which can resist high temperatures and corrosive environments. They are designed for environments with a maximum operating temperature of 800°F (426°C).

How PowerStream Nozzles Work |

|

|

|

|

With these nozzles, the atomizing fluid is supplied into the body of the nozzle where it is directed through the exit orifice, and deflected off the smooth, angled surface of the nozzle tip. The resultant spray shape is a wide-angle, deflected flat-fan pattern. |

|

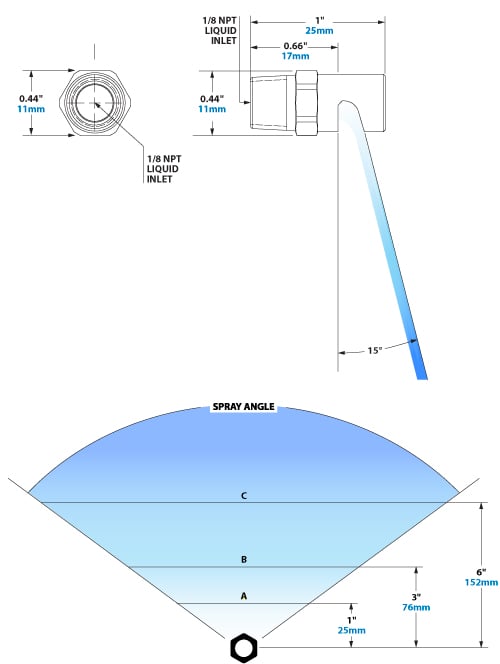

Spray DimensionsPowerStream Liquid Atomizing Nozzle(1/8 NPT Models) |

|||||

|

|||||

Model |

Pressure |

Spray Angle |

Width (inches) |

||

| DL8025SS | Degrees | A | B | C | |

| 7 PSI | 70 | 1.4 | 4.2 | 8.4 | |

| 20 PSI | 80 | 1.7 | 5.0 | 10.1 | |

| 60 PSI | 110 | 2.9 | 8.6 | 17.1 | |

| DL8030SS | Degrees | A | B | C | |

| 7 PSI | 80 | 1.7 | 5.0 | 10.1 | |

| 20 PSI | 100 | 2.4 | 7.2 | 14.3 | |

| 60 PSI | 105 | 2.6 | 7.8 | 15.6 | |

| DL8040SS | Degrees | A | B | C | |

| 7 PSI | 90 | 2.0 | 6.0 | 12.0 | |

| 20 PSI | 110 | 2.9 | 8.6 | 17.1 | |

| 60 PSI | 120 | 3.5 | 10.4 | 20.8 | |

| DL8050SS | Degrees | A | B | C | |

| 7 PSI | 120 | 3.5 | 10.4 | 20.8 | |

| 20 PSI | 120 | 3.5 | 10.4 | 20.8 | |

| 60 PSI | 130 | 4.3 | 12.9 | 25.7 | |

| DL8075SS | Degrees | A | B | C | |

| 7 PSI | 140 | 5.5 | 16.5 | 33.0 | |

| 20 PSI | 140 | 5.5 | 16.5 | 33.0 | |

| 60 PSI | 150 | 7.5 | 22.4 | 44.8 | |

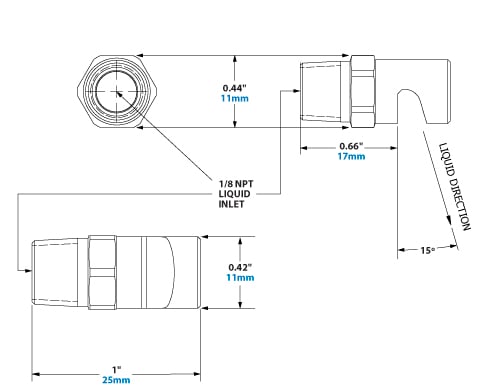

Dimensions & PerformancePowerStream Liquid Atomizing Nozzle(1/8 NPT Models) |

|||||

|

|||||

Model |

DL8025SS |

DL8030SS |

DL8040SS |

DL8050SS |

|

Inlet Connection |

1/8 NPT | 1/8 NPT | 1/8 NPT | 1/8 NPT | |

Capacity |

2.5 | 3 | 4 | 5 | |

Max Free Passage |

0.055" | 0.063" | 0.070" | 0.079" | |

Flow Rate

|

DL8025SS |

DL8030SS |

DL8040SS |

DL8050SS |

|

| 3 PSI | GPM | 0.15 | 0.17 | 0.22 | 0.27 |

| LPM | 0.57 | 0.64 | 0.83 | 1.02 | |

| 5 PSI | GPM | 0.19 | 0.22 | 0.27 | 0.34 |

| LPM | 0.72 | 0.83 | 1.02 | 1.29 | |

| 7 PSI | GPM | 0.20 | 0.25 | 0.33 | 0.42 |

| LPM | 0.76 | 0.95 | 1.25 | 1.59 | |

| 10 PSI | GPM | 0.24 | 0.31 | 0.40 | 0.50 |

| LPM | 0.91 | 1.17 | 1.51 | 1.89 | |

| 20 PSI | GPM | 0.36 | 0.45 | 0.59 | 0.74 |

| LPM | 1.36 | 1.70 | 2.23 | 2.80 | |

| 40 PSI | GPM | 0.50 | 0.67 | 0.86 | 1.09 |

| LPM | 1.89 | 2.54 | 3.26 | 4.13 | |

| 60 PSI | GPM | 0.64 | 0.83 | 1.06 | 1.32 |

| LPM | 2.42 | 3.14 | 4.01 | 5.00 | |

Model |

DL8075SS |

|

Inlet Connection |

1/8 NPT | |

Capacity |

7.5 | |

Max Free Passage |

0.094" | |

Flow Rate

|

DL8075SS |

|

| 3 PSI | GPM | 0.38 |

| LPM | 1.44 | |

| 5 PSI | GPM | 0.50 |

| LPM | 1.89 | |

| 7 PSI | GPM | 0.61 |

| LPM | 2.31 | |

| 10 PSI | GPM | 0.75 |

| LPM | 2.84 | |

| 20 PSI | GPM | 1.08 |

| LPM | 4.09 | |

| 40 PSI | GPM | 1.51 |

| LPM | 5.72 | |

| 60 PSI | GPM | 1.84 |

| LPM | 6.97 | |

Oops! Data fetch unsuccessful. Kindly hit refresh for a quick fix.