High Velocity Air Jet(s) with Stay Set Hose(s) and Magnetic Base

Applications

- Part cleaning

- Chip removal

- Part drying

- Liquid blowoff

- Part cooling

- Material conveying

- Part ejection

- Air assist

Advantages

- Reduced compressed air costs

- 10 dBA average noise reduction

- Conserve compressed air

- Improved blowoff performance

- Compact

- Improved safety

- Meets OSHA noise level requirements

- Meets OSHA pressure requirements.

- Improved production

High Velocity Air Jet with Stay set Hose & Magnetic Base - Materials

Brass - general purpose applications. Maximum temperature 400°F (204°C).

High Velocity Air Jet Accessories

Shim Set - Shims can be used to change the gap on the Model 6013 High Velocity Air Jet. Changing shims will alter air consumption, force, flow and vacuum capability. The Model 6313 Air Jet Shim Set for the High Velocity Air Jet includes a .006" (0.15mm) and a .009" (0.23mm) thick shim. A .015" (0.38mm) shim comes installed with the Model 6013 Air Jet.

Swivel Fittings - make it easy to adjust the aim of the Air Nozzles and Jets. Correct placement of the blowing angle can help optimize performance, reduce noise levels and improve efficiency. Swivel Fittings permit a movement of 25 degrees from the center axis for a total movement of 50 degrees. Type 303 or 316 Stainless Steel.

High Velocity Air Jet Performance | ||||

| Air Consumption | Force | Sound Level | ||

| SCFM | SLPM | Ozs | Grams | dBA |

| 22 | 622 | 20 | 567 | 82 |

*Force measured at 12" (305mm) from target with a .015" (0.38mm) shim installed Sound level measued at 3' (914mm) All measurements taken at 80 PSIG (5.5 BAR) | ||||

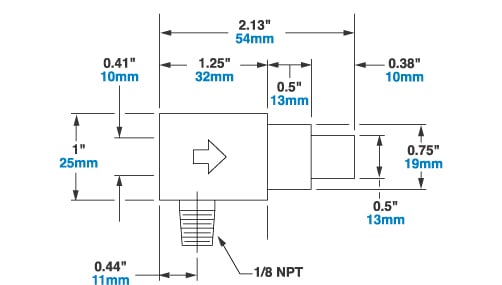

Dimensions - High Velocity Air Jet |

Models6013, 6013SS |

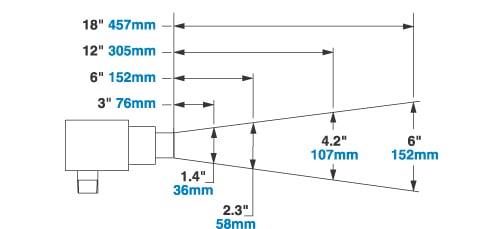

Airflow Pattern - High Velocity Air Jet |

Models6013, 6013SS |

How EXAIR Air Jets Work |

|

|

|

|

Air Jets utilize the Coanda effect (wall attachment of a high velocity fluid) to produce air motion in their surroundings. As illustrated above a small amount of compressed air (black arrows) is throttled through an internal ring nozzle above sonic velocity. A vacuum is produced, pulling large volumes of surrounding, or “free” air, through the jet (blue arrows). Both the outlet and inlet can be ducted for remote positioning. If the end is blocked, flow simply reverses at well below OSHA dead end pressure requirements. |

|

High Velocity Air Jet Dimensions and Airflow Pattern |

|

Air Jet Standards and Certifications

EXAIR Air Jets comply with OSHA's Safety Requirements, the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC). All sound level measurements are taken at 3 feet away.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.

Efficiency Lab

Does your company currently use a blowoff product similar to EXAIR’s that you’d like us to evaluate? Ship it to the EXAIR Efficiency Lab! Our qualified staff will test it for FREE, using EXAIR’s calibrated testing equipment. We’ll compare the performance of your existing product (air consumption, effectiveness, noise levels, efficiencies, etc) with the EXAIR Intelligent Compressed Air® products. The results will be published in a comprehensive report that includes a cost savings analysis. For most applications, EXAIR products can help you improve your efficiency AND typically pay for themselves in a matter of weeks.

To participate in our Efficiency Lab testing, please complete this Product Efficiency Survey to give us the details about your current application and blowoff set up. You can also feel free to contact an Application Engineer for more information at (800) 903-9247 or (513) 671-3322.

After completing the form, your product can be shipped to: Efficiency Lab, EXAIR, 11510 Goldcoast Dr., Cincinnati, OH 45249-1621

This offer is available to all customers in the U.S. and Canada only. Some restrictions might apply.

Products must be shipped to EXAIR freight prepaid. EXAIR will pay the return shipping via UPS ground.

If you cannot send in your product, fill out this Product Efficiency Survey to give us the details about your current application and we will estimate the savings for you.

Selecting the Right Air Nozzle

EXAIR manufactures a wide selection of Air Nozzles and Jets, which are divided into two groups. The first group of Standard Force Air Nozzles includes Air Nozzles and Jets that deliver force up to 22 ounces (624 grams) and are suitable for most applications. The second group of High Force Air Nozzles includes Air Nozzles that produce high force up to 23 lbs (10,43 kg) where additional reach and force are required.

- Type 303 Stainless Steel - high temperatures and corrosive environments. Max temp 800°F (426°C)

- Type 316 Stainless Steel - high temperatures, corrosive environments, and mechanical wear. Max temp 1000°F (538°C)

- Brass - general purpose applications. Max temp 400°F (204°C)

- Zinc - aluminum alloy- general purpose applications. Max temp 250°F (121°C)

- PEEK - replaces metals in harsh environments. Offers chemical resistance and is non-marring. Max temp 320°F (160°C)

Safe and Efficient Use of Compressed Air

The inefficient use of compressed air for blowoff applications may create problems due to the energy costs, noise level and potential danger to personnel who are exposed to high pressure air. Open air pipes, copper tubes and drilled pipes are a few of the common abusers. They consume tremendous amounts of energy and often produce noise levels over 100 dBA.

Reduce Energy Costs

The best way to cut energy costs is through proper maintenance and use of the compressed air system. Leaks and dirty filters require maintenance on a regular basis. Energy savings can also be realized when replacing outdated compressor motors and controls with high efficiency models that often pay for themselves in a short period of time.

The most important factor to dramatically boost efficiency is proper use. Using engineered products like EXAIR's Super Air Nozzles can cut operating costs since they use only a fraction of the compressed air of typical blowoffs. In addition, all of EXAIR's Air Nozzles and Jets can be cycled on and off with an instantaneous response. EXAIR's EFC is an electronic flow control that limits compressed air use by turning on the air only when a part is present.

Reduce Noise Levels

High noise levels are a common problem for many plants. Compressed air noise often exceeds OSHA noise level exposure requirements, resulting in hearing loss to those working in close proximity. Noisy blowoffs at 80 PSIG (5.5 BAR) that produce noise levels of 100 dBA can be reduced to only 74 dBA when using a Super Air Nozzle. At that pressure, it is still possible to obtain hard-hitting force without the high noise.

Eliminate Harmful Dead End Pressures

Air can be dangerous when the outlet pressure of a hole, hose or copper tube is higher than 30 PSIG (2 BAR). In the event the opening is blocked by a hand or other body part, air may enter the bloodstream through the skin, resulting in a serious injury. All of the Air Nozzles and Jets manufactured by EXAIR have been designed for safety. All are safe to be supplied with higher pressure compressed air and meet OSHA standard 29 CFR 1910.242(b).

Stay Safe

If an air hose, open pipe, or copper tube has an outlet pressure that's greater than 30 PSIG, a worker can be seriously injured or killed if they block the opening with a hand or other body part. At that pressure, it is possible for air to enter the bloodstream through the skin (Occupational Safety and Health Administration (OSHA) standard CFR 1910.242(b)). Every one of EXAIR's Air Nozzles have been designed to prevent that blockage at any pressure. If you are currently using open pipe or commercial nozzles for your blowoff or cooling operation, you're already well aware of how loud it can get. These devices can produce noise levels that are well over 100 dBA. OSHA warns that an unprotected worker can only work for 2 hours in the proximity of 100 dBA noise before permanent hearing loss will occur (OSHA standard 29 CFR 1910.95(a)). For instance, EXAIR's Model 1100 Super Air Nozzle has a noise level of only 74 dBA at 80 PSIG yet still produces .8 lbs of strong blowoff force!Save Money

One item that is often overlooked when auditing your company's expenditures is the cost of compressed air. On a 24 hour production line, reducing average compressed air use by even one Standard Cubic Foot per Minute (SCFM) can result in a savings of over $130 per year and, replacing open tubing or a commercial nozzle with an engineered nozzle from EXAIR can reduce air use by 50-70%!Save Time

Now that you know why you should pick EXAIR's engineered nozzles, here's an easy way to do it! EXAIR's Blowoff Guide contains pictures, specifications, and examples that make it a breeze to choose the right Air Nozzle or Safety Air Gun for your application. Click Here to Order EXAIR's Free Blowoff Guide!Saving Money and Compressed Air

OSHA Maximum Allowable Noise Exposure | |||||||

| Hours per day (constant noise) | 8 | 7 | 4 | 3 | 2 | 1 | 0.5 |

| Sound level dBA | 90 | 91 | 95 | 97 | 100 | 105 | 110 |

| OSHA Standard 29 CFR - 1910.95(a) | |||||||

The table above shows the air consumption for typical homemade blowoffs.

Consider the following example where a Model 1102 Mini Super Air Nozzle replaces a 1/8" open pipe. The compressed air savings is easy to calculate and proves to be dramatic. Payout for Air Nozzles and Jets, including filter and installation cost is measured in weeks - not years, as is the case for other cost reduction equipment. Based on a 40 hour work week, 52 weeks a year.

- Example: Existing blowoff is 1/8" open pipe at 80 PSIG (5.5 BAR) supply. Air consumption, from the table above, is 70 SCFM (1,981 SLPM).

- Use a 1/8 FNPT Model 1102 Mini Super Air Nozzle also at 80 PSIG (5.5 BAR) supply. Air consumption is 10 SCFM (283 SLPM).

- Compressed air saved = 70 - 10 = 60 SCFM (1,981 - 283 = 1,698 SLPM).

- For this example, the blowoff is continuous. If the duty cycle was 20%, then air saved would be 60 x .2 = 12 SCFM (1,698 x .2 = 340 SLPM).

- Most large plants know their cost per 1,000 standard cubic feet of compressed air (10,000 standard liters). If you don't know your actual cost per 1,000 SCF, $0.25 is a reasonable average to use. (Cost per 10,000 standard liters is approximately $0.089.)

- Dollars saved per hour = SCFM saved x 60 minutes x cost/1,000 SCF (SLPM saved x 60 min x cost/10,000 SL) = 60 x 60 x $0.25/1,000 (= 1,698 x 60 x $0.089/10,000)

- = $0.90/hour

- = $0.90/hr. is $36.00/week and

- = $1,872.00/year savings for One nozzle!

-

High Velocity Air Jets are available in brass or Type 303 stainless steel material.

High Velocity Air Jets are available in brass or Type 303 stainless steel material. -

A combination of Model 6013 High Velocity Air Jets dry this chainsaw cylinder head.

A combination of Model 6013 High Velocity Air Jets dry this chainsaw cylinder head. -

These Air Jets are used to remove residual coolant and debris from machined parts.

These Air Jets are used to remove residual coolant and debris from machined parts. -

A High Velocity Air Jet with Stay Set Hose and Magnetic base provides positioning and mounting capabilites.

A High Velocity Air Jet with Stay Set Hose and Magnetic base provides positioning and mounting capabilites.