Gen4® Super Ion Air Knife™

Powerful static eliminator prevents jamming, tearing, shocks and dust up to 20' away!

EXAIR's Gen4 Super Ion Air Knife offers 34% improved performance at low pressures allowing you to achieve the same or better results, which saves compressed air and money. They remove static electricity from plastics, webs, sheet stock and other product surfaces where tearing, jamming or hazardous shocks are a problem. The laminar sheet of air sweeps surfaces clean of static, particulate, dust and dirt. Production speeds, product quality, and surface cleanliness can improve dramatically.

At a powerful 40:1 air amplification ratio, the Gen4 Super Ion Air Knife floods an area or surface with static eliminating ions – up to 20 feet (6.1m) away. Uniform airflow across its length prevents misalignments to critical surfaces such as webs. The Gen4 Super Ion Air Knife is electrically powered, is shockless and has no moving parts. It also requires only 3.7 SCFM of compressed air per foot of length at 5 PSIG (105 SLPM per 300mm of length at 0.3 BAR).

Specifications |

|

Certifications - The Gen4 Super Ion Air Knife and Gen4 Power Supply are UL Component Recognized to U.S. and Canadian safety standards, and are CE and RoHS compliant. |

|

Electrical - For use with 5 kVrms, 5 milliamperes (max.) power supply. |

|

Electrical Hazard - Shockless (less than 40 microamperes short circuited). |

|

Do not use near flammable materials or gases. |

|

Materials of Construction: |

|

Metal Parts - Aluminum |

|

Plastic Parts - UL rated 94 HB |

|

Emitter - Stainless Steel |

|

Maximum Ambient Temperature - 165°F (74°C) |

|

Shims - Thicker shims can be installed easily if additional hard-hitting velocity is required. |

|

Compressed Air - 1/4 NPT inlet provided on each end and bottom. |

|

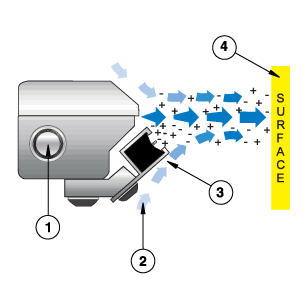

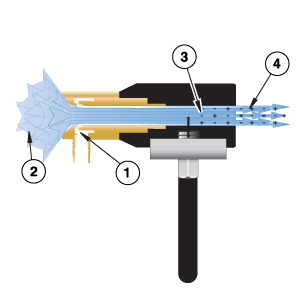

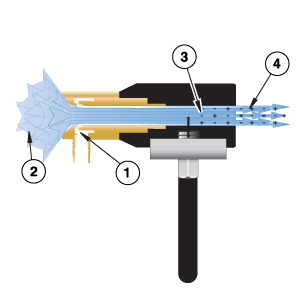

How the Gen4 Super Ion Air Knife Works

Compressed air flows through an inlet ① into the plenum chamber of the Gen4 Super Ion Air Knife. The flow is directed to a precise, slotted orifice. As the primary airflow exits, it creates a uniform sheet of air across the entire length that immediately pulls in surrounding room air ②. An electrically powered Gen4 Ionizing Bar ③ fills the curtain of air with positive and negative charges. The airstream delivers these static eliminating ions to the product surface ④ where it instantly neutralizes static and cleans off dust and other particulates.

Intellistat® Ion Air Nozzle

Create a Hands-Free Static Removal Station

Rated for Class 5 Clean Rooms

The patented† Intellistat® Ion Air Nozzle produces ionized compressed air to neutralize static and remove troublesome particulates during clean processes, test procedures and sensitive assembly work. With a +/-30 volt balance, the Intellistat was designed to use minimal compressed air while delivering precise blow-off and exceptional static decay rates capable of reducing 1000 volts to less than 100 in under one second. A low voltage transformer converting 120V or 240V to 24V assures electrical safety, while EXAIR’s engineered air nozzle meets OSHA compressed air standards.

Including a compact stainless steel adjustable mounting bracket, the Intellistat Ion Air Nozzle can be mounted to benchtops and machine frames, for example, to provide hands-free operation when needing both hands to package, test or assemble parts and products. The Intellistat Ion Air Nozzle is designed with other convenient features including the 6mm push-in air connection, and green and red LEDs which indicate proper functionality. It is a dependable and low maintenance solution made from durable dissipative polycarbonate for applications requiring non-conductivity such as circuit board or electronic manufacturing. It is ideal for sterile environments such as laboratories, clean rooms or scientific testing facilities.

†Patent Numbers: EU: EU Regd. Des. No. 009025463-0001, UK Registered Design No. 6211314

Specifications |

|

Certifications - The Intellistat Ion Air Nozzle is UL listed, and CE and RoHS compliant. |

|

Class 5 Rating for Clean Rooms and Controlled Environments - per ISO 14644-1. |

|

Power Supply Input - 100-240V — 50/60 Hz 0.7A Max |

|

Electrical Hazard - Shockless (less than 40 microamperes short circuited). |

|

Do not use near flammable materials or gases. |

|

Operating Temperature - 32°F to 105°F (0-41°C) |

|

Materials of Construction - Static resistant polycarbonate |

|

Emitter - Stainless Steel |

|

Gas Input - 30 psig - 125 psig (clean, dry compressed air or nitrogen) |

|

Air Connection - 6mm tube |

|

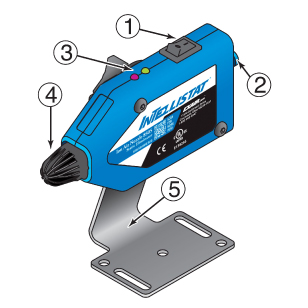

How the Intellistat Ion Air Nozzle Works

After connecting the 24V power supply and compressed air supply, turning on the power switch ① activates the static eliminating ions and air flow from the push-in fitting ②. Proper functionality is indicated by the red and green LEDs ③. The OSHA compliant, non-marring nozzle ④ provides quiet and safe performance. A compact mounting bracket ⑤ is included to provide hands-free operation.

Gen4® Super Ion Air Wipe™

Ring of ionized airflow clamps around the part!

Neutralizes and cleans continuous moving surfaces!

The Gen4 Super Ion Air Wipe provides total coverage of the part moving through it. It produces a high volume, high velocity charged airflow that attaches itself to the surface of the production part and wipes it down with static eliminating ions. The laminar airflow stays attached to the surface and is effective far away from where the Gen4 Super Ion Air Wipe is mounted. Using an optional pressure regulator provides infinite control of the air volume and velocity, allowing optimal coverage of the production piece.

Until now, there has been no easy way to provide uniform coverage around a continuously moving part. It is very difficult to line up and feed continuously moving materials (such as wire, tubing or extrusions) through a solid blowoff ring. Arranging a series of ionizers around the surface would provide uneven airflow and prove to be costly. The split design of the Gen4 Super Ion Air Wipe solves that problem by making it easy to clamp around the surface of the material moving through it, eliminating the need for threading or the positioning of several linear ionizers.

Specifications |

|

Certifications - The Gen4 Super Ion Air Wipe and Gen4 Power Supply are UL Component Recognized to U.S. and Canadian safety standards, and are CE and RoHS compliant. |

|

Electrical - For use with 5 kVrms, 5 milliamperes (max.) power supply. |

|

Electrical Hazard - Shockless (less than 40 microamperes short circuited). |

|

Do not use near flammable materials or gases. |

|

Materials of Construction: |

|

Metal Parts - Aluminum |

|

Plastic Parts - UL rated 94 HB |

|

Emitter - Stainless Steel |

|

Maximum Ambient Temperature - 165°F (74°C) |

|

Shims - Thicker shims can be installed easily if additional hard-hitting velocity is required. |

|

Compressed Air - 1/4 NPT inlet provided. |

|

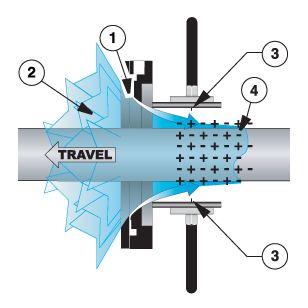

How the Gen4 Super Ion Air Wipe Works

The Gen4 Super Ion Air Wipe incorporates a Super Air Wipe and a split ionizing collar, energized by a power supply. Compressed air is ejected through the small ring nozzle of the Super Air Wipe at high velocity ①. A conical 360° ring of air is created that induces high volumes of surrounding air ②. The airflow passes through the collar and is ionized by two replaceable emitter points ③. That high velocity, ionized airstream attaches itself to the surface of the material running through the Gen4 Super Ion Air Wipe ④, uniformly eliminating the static electricity and removing any contaminants from the surface.

Have More Questions About Static Eliminators?

| 1.800.903.9247 (toll free in U.S. & Canada) |

| [email protected] |

| Chat Now |

Gen4® Ion Air Cannon™

Quiet, efficient, concentrated flow of ionized air

removes static and dust!

EXAIR's Gen4 Ion Air Cannon neutralizes static electricity and cleans at distances up to 15 feet (4.6m) with no moving parts. It is ideal for those hard to reach spaces or confined areas that require a concentrated flow of static eliminating ions. With an optional pressure regulator, the air volume and velocity are infinitely adjustable over a wide range, for light to heavy duty applications.

A small amount of compressed air is used to entrain a high volume flow of surrounding air. This combined stream is ionized by an emitter point (shockless) and delivered to the charged surface. It requires only 10 PSIG (0.7 BAR) for most applications. The compact design saves bench space and can be permanently mounted.

Specifications |

|

Certifications - The Gen4 Ion Air Cannon and Gen4 Power Supply are UL Component Recognized to U.S. and Canadian safety standards, and are CE and RoHS compliant. |

|

Electrical - For use with 5 kVrms, 5 milliamperes (max.) power supply. |

|

Electrical Hazard - Shockless (less than 40 microamperes short circuited). |

|

Do not use near flammable materials or gases. |

|

Materials of Construction: |

|

Metal Parts - Aluminum |

|

Plastic Parts - UL rated 94 HB |

|

Emitter - Stainless Steel |

|

Maximum Ambient Temperature - 165°F (74°C) |

|

Shims - Thicker shims can be installed easily if additional hard-hitting velocity is required. |

|

Compressed Air - 3/8 NPT inlet provided. |

|

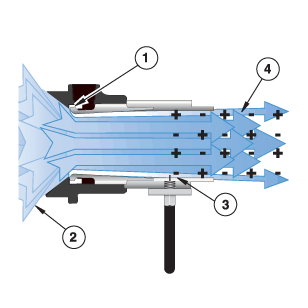

How the Gen4 Ion Air Cannon Works

The Gen4 Ion Air Cannon incorporates a Super Air Amplifier™ and ionizing collar, energized by a power supply. A small amount of compressed air is injected into the barrel of the cannon ① inducing a high volume flow of surrounding air to flow through it ②.

A replaceable emitter point (shockless) at the discharge end of the cannon ③ ionizes the entire airstream. The result is a high volume, conical flow of ionized air ④ capable of eliminating static and cleaning at distances up to 15 feet (4.6m). Because more than 90% of the ionized air is induced, the Gen4 Ion Air Cannon produces maximum airflow at minimum air consumption.

Gen4® Ion Air Jet™

Air saving Gen4 Ion Air Jet is a highly effective spot cleaner!

EXAIR's Gen4 Ion Air Jet delivers a concentrated airflow that can cover a precise spot without disturbing other areas. This quiet, focused airstream provides incredibly fast static decay rates and cleaning ability. The Gen4 Ion Air Jet is the ideal way to remove static and dust from small parts prior to shrink wrapping, packaging, printing, painting or finishing. The Gen4 Ion Air Jet induces surrounding airflow at a ratio of 5:1, minimizing compressed air use and maximizing ionized airflow.

For permanent mount applications, the compact Ion Air Jet is the best choice since it is lightweight and easy to install using the 1/8 NPT male inlet.

Specifications |

|

Certifications - The Gen4 Ion Air Jet and Gen4 Power Supply are UL Component Recognized to U.S. and Canadian safety standards, and are CE and RoHS compliant. |

|

Electrical - For use with 5 kVrms, 5 milliamperes (max.) power supply. |

|

Electrical Hazard - Shockless (less than 40 microamperes short circuited). |

|

Do not use near flammable materials or gases. |

|

Materials of Construction: |

|

Metal Parts - Brass and Stainless Steel |

|

Plastic Parts - UL rated 94 HB |

|

Emitter - Stainless Steel |

|

Maximum Ambient Temperature - 165°F (74°C) |

|

Compressed Air - 1/8 NPT inlet provided. |

|

How the Gen4 Ion Air Jet Works

The Gen4 Ion Air Jet incorporates a High Velocity Air Jet and electrically energized emitter point. A small amount of compressed air is injected into the air jet ① inducing a high volume flow of surrounding air ② to pass through it.

The emitter point (shockless) at the discharge end of the Air Jet ③ ionizes the entire airstream. The result is a high volume flow of ionized air ④ capable of neutralizing high static charges in fractions of a second. An optional filter and regulator clean the compressed air and allow infinite adjustment of airflow and velocity.

Gen4® Stay Set Ion Air Jet™

Effective spot cleaning and easy positioning

with Stay Set Hose and magnetic mount!

EXAIR's Gen4 Ion Air Jet delivers a concentrated airflow that can cover a precise spot without disturbing other areas. This quiet, focused airstream provides incredibly fast static decay rates and cleaning ability. The Gen4 Ion Air Jet is the ideal way to remove static and dust from small parts prior to shrink wrapping, packaging, printing, painting or finishing.

The Gen4 Stay Set Ion Air Jet comes complete with a magnetic base that allows easy mounting and portability on a machine, a bench, or other surface. A shutoff valve on the base provides infinite control of the force and flow.

Specifications |

|

Certifications - The Gen4 Stay Set Ion Air Jet and Gen4 Power Supply are UL Component Recognized to U.S. and Canadian safety standards, and are CE and RoHS compliant. |

|

Electrical - For use with 5 kVrms, 5 milliamperes (max.) power supply. |

|

Electrical Hazard - Shockless (less than 40 microamperes short circuited). |

|

Do not use near flammable materials or gases. |

|

Materials of Construction: |

|

Metal Parts - Brass and Stainless Steel |

|

Plastic Parts - UL rated 94 HB |

|

Emitter - Stainless Steel |

|

Maximum Ambient Temperature - 165°F (74°C) |

|

Compressed Air - 1/4 NPT inlet provided. |

|

How the Gen4 Stay Set Ion Air Jet Works

The Gen4 Stay Set Ion Air Jet incorporates a High Velocity Air Jet and electrically energized emitter point. A small amount of compressed air is injected into the air jet ① inducing high volume flow of surrounding air ② to pass through it.

The emitter point (shockless) at the discharge end of the gun ③ ionizes the entire airstream. The result is a high volume flow of ionized air ④ capable of neutralizing high static charges in fractions of a second. An optional filter and regulator clean the compressed air and allow infinite adjustment of airflow and velocity.