Cooling

dramatically reduce compressed air usage and noise. They offer a quiet, hard-hitting curtain of air for cooling, blowoff, cleaning or drying. They are surprisingly quiet at 68 dBA, have a uniform airflow and are available in 3” to 108” lengths, so very large surfaces can be cooled.

Cooling Calendar Rolls

Customer thermoforms using heated calendar rolls. The problem they were experiencing was distortion of the product. Since the web is not as wide as the roll,the heat from the ends is not absorbed. This causes an uneven heating surface, distorting the web. Using a Model 110003 3" (76mm) Aluminum Super Air Knife to blow cooling air on the exposed surfaces of the roll, they were able to remove enough heat to eliminate the product distortion.

stop electronic control downtime due to heat, dirt and moisture. They maintain NEMA 4, 4X and 12 integrity. They are a low cost, reliable way to cool and purge electronic control panels. They are easy to install, quiet and come in a large assortment of sizes and styles.

Cabinet Cooler Easily Handles Large Heat Load

Customer is an industrial reseller whose customer had a big heat issue with one of their electrical control panels. To properly handle the heat load, a Model 4380 Nema 12 Dual Cabinet Cooler System was required. It will provide 5600 BTU/hr of cooling power. It also includes a thermostat control so the unit will turn off when not needed, to save compressed air consumption. It will maintain an internal temperature of 95°F inside the enclosure to keep the equipment operating at a safe temperature with no more heat-related shutdowns.

reduce noise levels and air costs. They produce outlet flows up to 25 times and compressed air consumption, using compressed air as the power source. Available with forces from 2 ounces to 23 pounds! Large selection with Standard Force and High Force models in Type 303 or Type 316 Stainless Steel, Brass, Zinc Aluminum and PEEK materials.

Universal Blow Off Station

A custom machine builder was charged with building a "one size fits all" blow off manifold. His customer is doing thermal printing and depending on the artwork, different areas on the sheet need cooling. They do not want to cool the entire sheet as it would affect their process. They just need to get the thermal printed area down to a temperature close to the rest of the sheet. Installing an array of Model 1009 Adjustable Air Nozzles on a manifold, they were able to build a universal cooling station. With the adjustablity of these nozzles, they could be turned on and off to fit the needs for a particular printing job.

can be used to replace messy mist systems to improve dry machining with clean, cold air. The Cold Gun produces a stream of air at 50°F (28°C) below supply air temperature. Improves production rates, prevents burning, extends tool life and more!

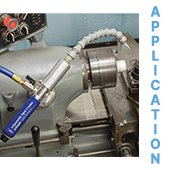

Maintaining Tolerances On A Grinding Operation

A steel casting company is using a Model 5215 Cold Gun to remove heat from steel alloy castings gates on a grinding application. The more heat they can keep from the grinding wheel and from the casting gate, the closer they are to tolerance on the secondary polishing/blending application.

are excellent spot cooling solutions for cooling solder, setting hot melts, cooling gas samples and more. Low cost, maintenance free, instant cold air. They include a magnetic mount for ease of positioning.

Removing Heat From A Cutter Blade

A custom machinery manufacturer is building a cutting machine for a filter manufacturer. They have a new filter media with metal screens on both sides that they are required to cut to size. The metal screen material is heating up the cutting blade and causing it to melt the filter media. This results in a scrapped part. They have installed a Model 3925 Adjustable Spot Cooler to blow cold air on the cutting blade to remove enough heat to prevent the blade from melting the filter media and eliminate any defects due to heat buildup.

can cool, vent, exhaust, dry and clean. They are a simple, low cost way to move air, smoke, fumes and light materials. Quiet, efficient Air Amplifiers will create output flows up to 25 times their consumption rate.

Super Air Amplifier Removes Heat From Hot Glue Process

This customer builds special purpose equipment, primarily for the electronics manufacturing industry. One of these products has magnets that are hot-glued in place. They were having problems with excessive heat building up in this part of the machinery, which was unable to be removed through the standard ventilation ducts and fans. They installed a Model 120022 2" (51mm) Super Air Amplifier, which quickly and quietly exhausts the hot air from the hot-glue chamber, keeping the temperature low enough for effective and safe operation.

are an excellent spot cooling solution. Excellent for cooling machining operations, setting hot melts, cooling gas samples and more. Low cost, maintenance free, instant cold air.

Vortex Tube Replaces Water Chiller at Candy Plant

This chocolate covered candy manufacturer uses old water chilled cooling plates to cool the chocolate from the “bottomer” which applies chocolate to the bottom of the candy. The bottom chocolate passes over the chill plate and hardens prior to the chocolate enrobing process which covers the rest of the candy. The old water chillers continually develop leaks and create messes around the plant. They have started to remove the water chillers and replace them with EXAIR Model 3230 Vortex Tubes. The Vortex Tubes provide cold air through the chill plate without creating any mess or maintenance issue and lowers maintenance costs.

atomize fluids (most commonly water) in a range of spray patterns for a variety of uses. Cooling spray is very easily adjusted to exactly what you need for each application. They are available in Standard and No Drip Models with a large assortment of patterns. 1/8 NPT, 1/4 NPT and 1/2 NPT sizes.

Cooling Copper Sheets

A metal extrusion company was looking for a way to cool their thin copper sheets as they where formed through a press. The purpose was to cool the material before it was wound into a roll.

The sheet was only 2mm (0.08”) thick but was 48” wide, so they used three Model AD1010SS Internal Mix Deflected Flat Fan Air Atomizing Nozzles to create a fine mist to cool the copper as it passed under.