Your Cart

You have no items in your shopping cart.

Close

Close  COOLING

COOLING

Often needed during manufacture to prevent damage to machinery and parts.

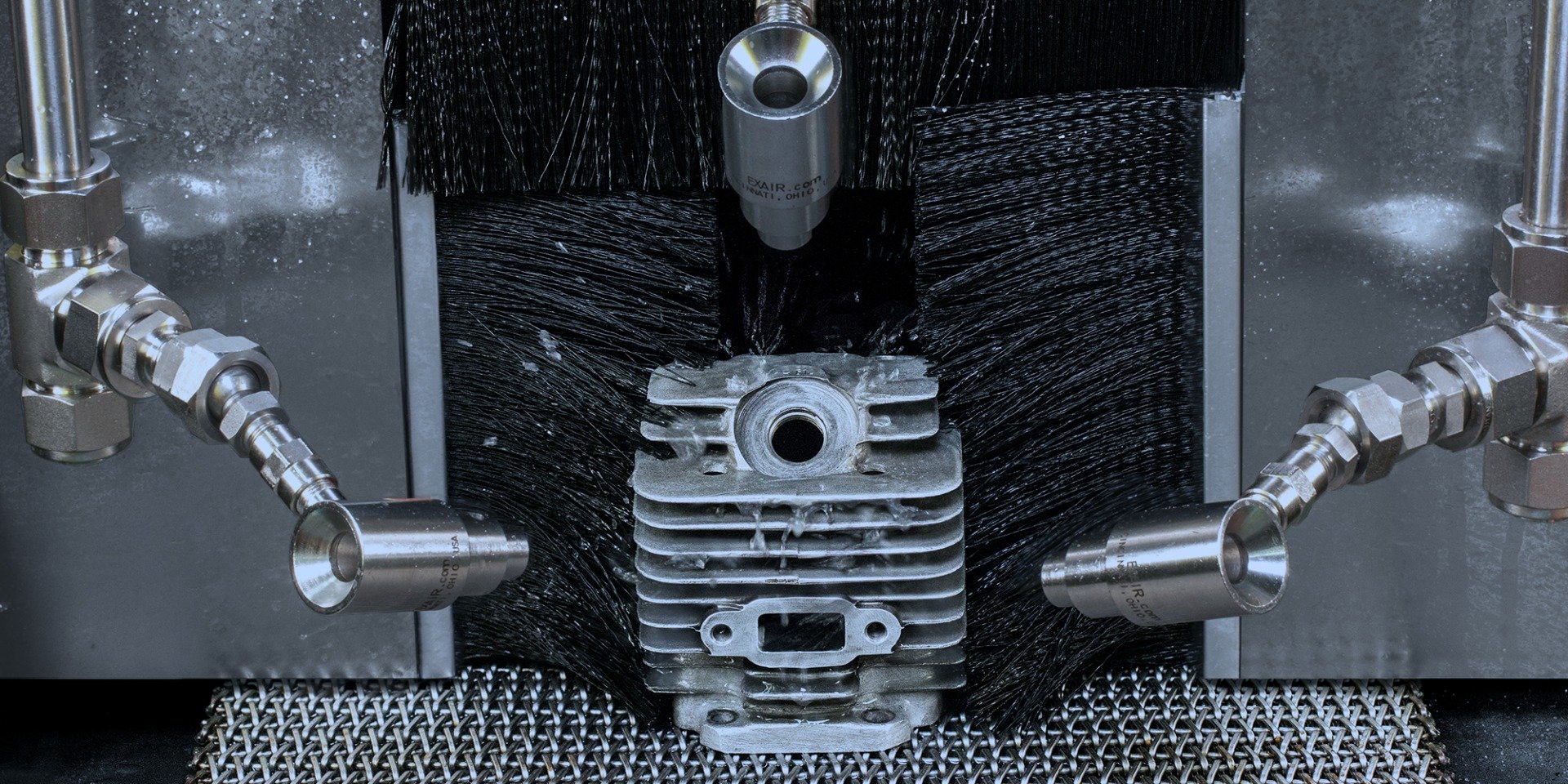

CLEANING

CLEANING

Needed between manufacturing processes and prior to packaging.

COATING

COATING

Used in many production and finishing operations.

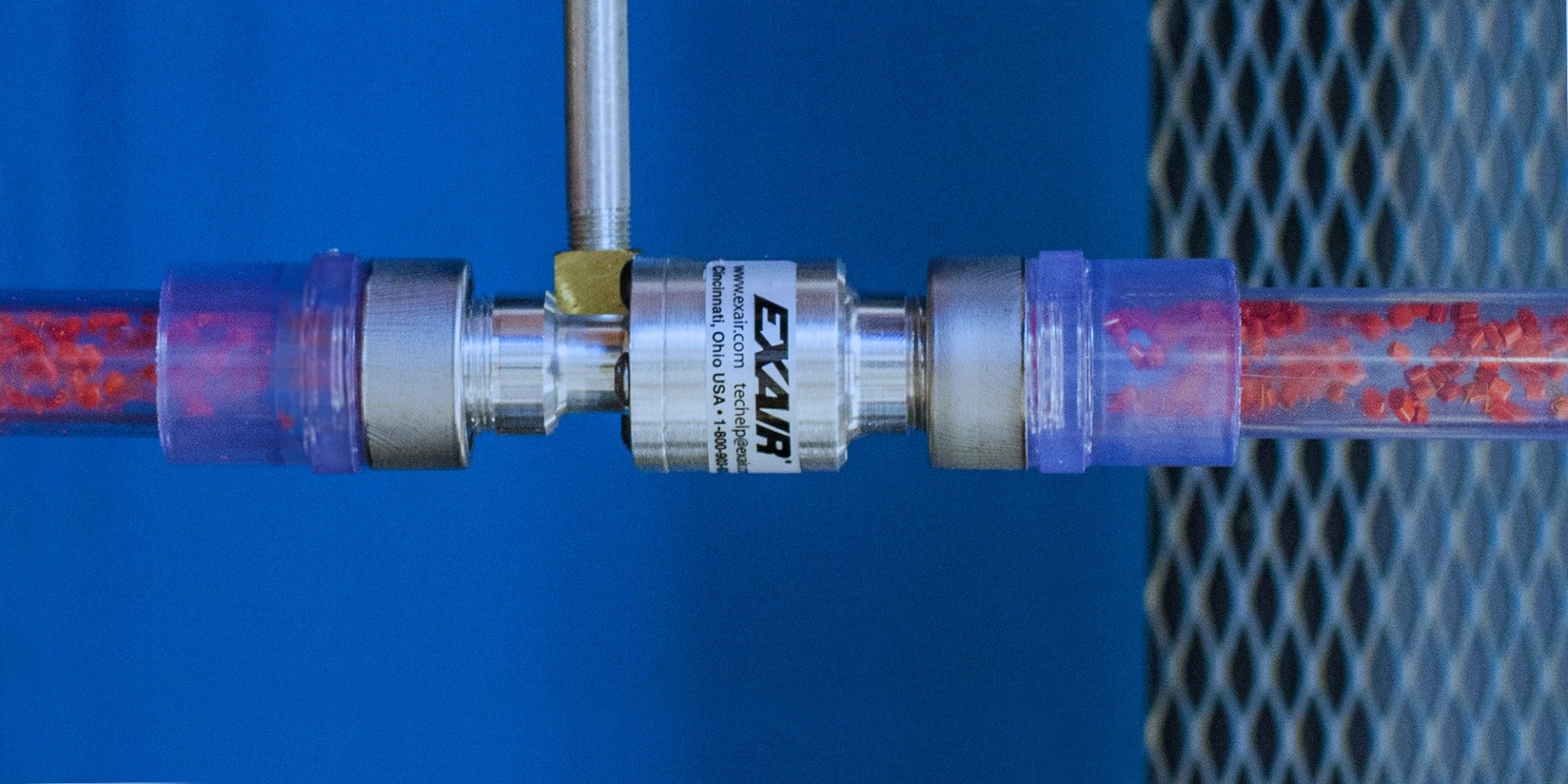

CONVEYING

CONVEYING

Many bulk components, finished products, and scrap can be quickly and efficiently moved with air.

DRYING

DRYING

Part dry is often required between production processes and prior to packaging.

INDUSTRIAL HOUSEKEEPING

INDUSTRIAL HOUSEKEEPING

Most manufacturing processes produce scrap that has to be cleaned up - with industrial-strength tools.

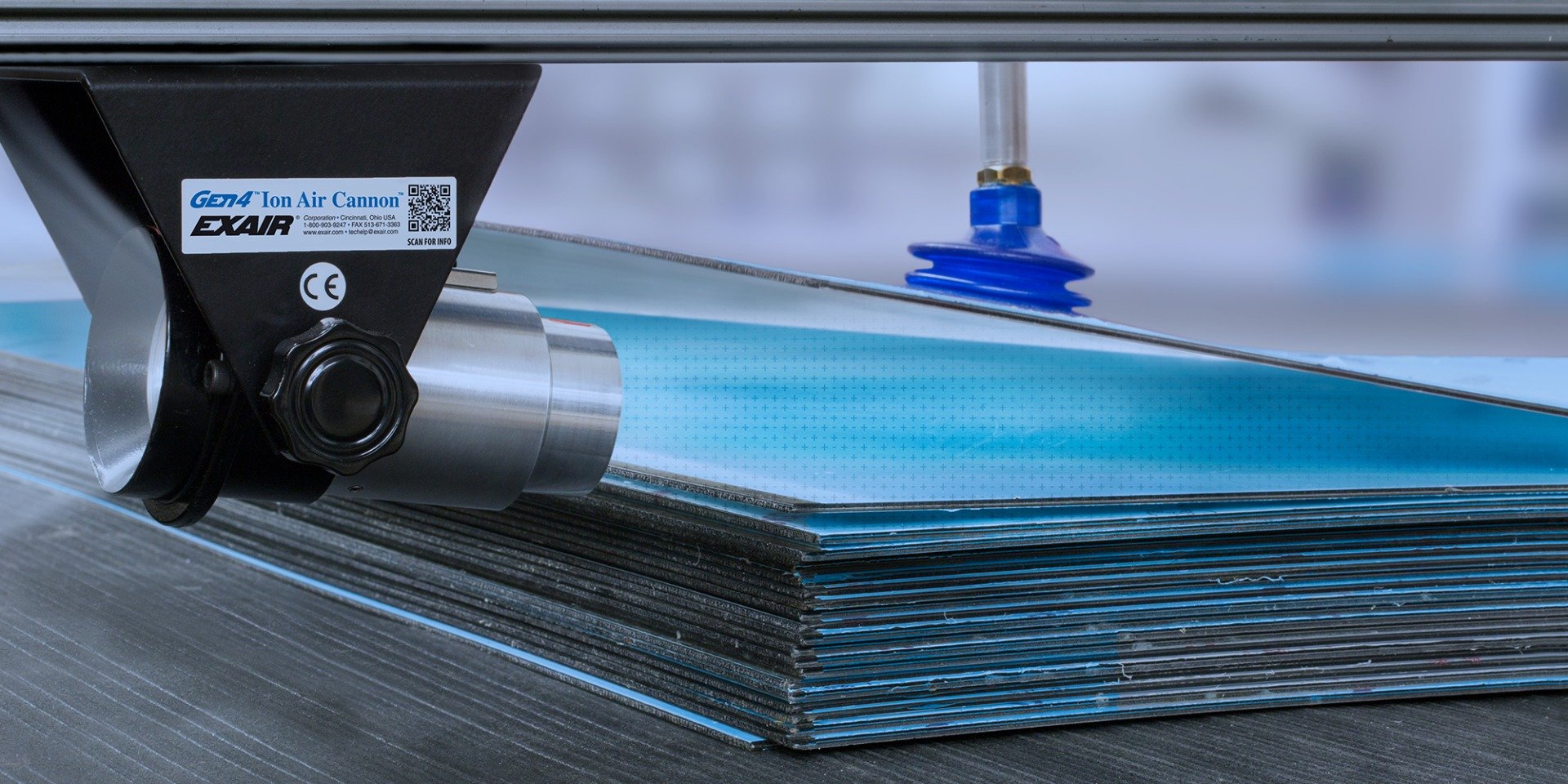

STATIC ELIMINATION

STATIC ELIMINATION

Often needed during manufacture to prevent damage to machinery and parts.

CONSERVATION & OPTIMIZATION

CONSERVATION & OPTIMIZATION

Conserving compressed air, lowering noise levels and reducing waste are very important in industrial applications.

Creating an account has many benefits: